Construction Building Grade (HPMC )Hydroxypropyl methyl cellulose

Mixed cementitious mortars have become a very important part of the mortar industry in Global and play anindispensable role due to the market promotion and national support of policy. In development of mortars, cellulose ether is animportant activist.

Ordinary mortar is economically demanding in which cement level is small, but the requirements for its operating and machine spraying properties are still high, so sand grading and additives are important. In addition, mechanical application will become a definite tendency of development of ready-mixed mortar, cellulose ether will make mechanical application possible.

Product Features

Increase water demand.

High water retention, prolong the operating time of the material, improve the working performance, avoid the phenomenon of crusting, and help to improve the mechanical strength of the material.

Improved operating performance, provide lubrication and uniform texture, so that the surface of the material is easier to wipe, thus improving the construction efficiency, and improve the resistance to cracking of putty.

Improve homogeneity, and improve vertical flow resistance.

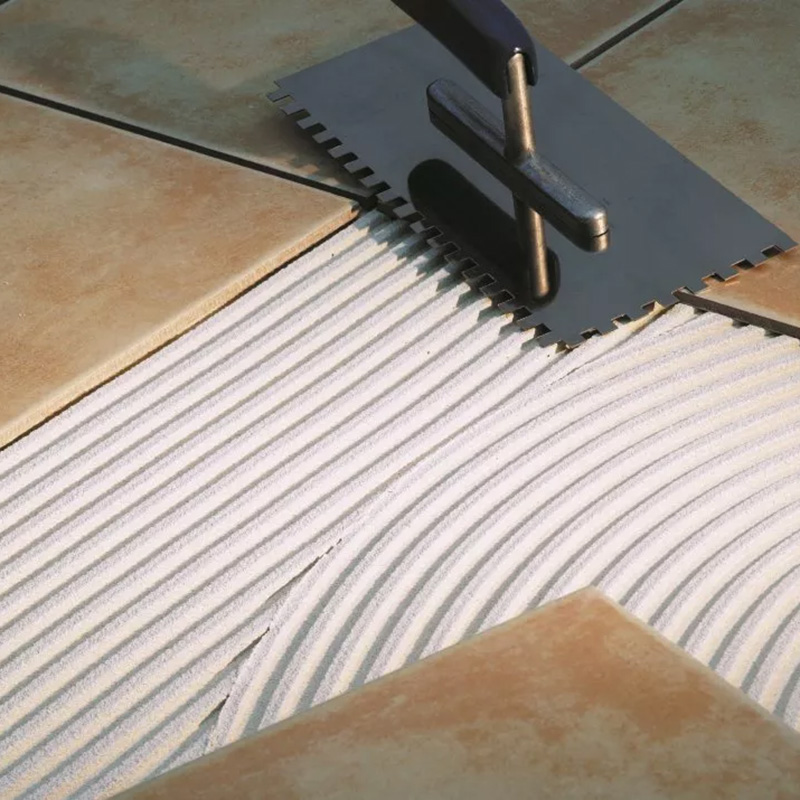

HPMC for tile adhesive

Ceramic tiles have high performance and excellent work efficiency when pasted on various substrates. Skid resistance and better opening time are the key to better adhesive requirements.

HPMC for wall putty

HPMC is non-ionic cellulose ether made from natural cotton fiber under series of chemical processing. It’s odorless, tasteless and non-toxic white powder, can be dissolved in normal water to form a transparent viscous solution with the properties of thickening,binding, dispersing, emulsifying, film coating, suspending, absorbing, gelling, water retention and colloid protection.

cellulose ethers impart the following excellent properties to mortar:

一Optimized wetting ability to the substrate

一 Advanced water retention ability

一 good spraying and pumping performance

一 Improve cement hydration by bonding strength

Product Description

1) Appearance: HPMC is a nonionic cellulose ether, white grayish-white powder or granule,odorless and flavorless, soluble in cold water, glacial acetic acid, ethanol, methanol and propylene glycol, slightly soluble in acetone depending on the degree of substitutions, practically insoluble in hot water, ethylene glycol and toluene. HPMC is dissolved in a mixture of 10% methanol and 90% methylene chloride to form colloidal solutions.

2) The solution of HPMC has surface activity, high transparency, and stable performance. When heated at certain temperature, the solution becomes cloudy or forms flocculent gel. However, the solution becomes clear again after cooling. Different types of HPMC have different gelation temperatures. The solubility varies with the viscosity. The lower the viscosity, the higher solubility it has. The different types of HPMC are different in some properties and their solubility in water is not affected by pH.

3) Particle sizes: 100% pass rate in 80 mesh.

4) Apparent density: 0.25-0.70 g/mL (usually about 0.5 g/mL),specific density 1.26-1.31mL.

5) Color change temperature:190-200°C; Carbonization temperature:280-300°C.

6) Surface tension:42-56 dyn/cm (2% aqueous solution).

7) The higher methoxy content in HPMC, the lower gelation temperature, and the higher solubility in water and surface activity.

8) HPMC has some other characteristics, for example, thickening property, pH stability, retention of water, excellent film-forming property, good disperse and adhesion ability.

Detail parameters

| Item | Index |

| Content of Methoxyl (%) | 24.0-30.0 |

| Content of Hydroxy propyl (%) | 7.0-12.0 |

| Temperature of gelation | 54℃—90℃ |

| Moisture | 5% max |

| Ash | 5% max |

| PH value | 6—8 |

| Appearance | White powder |

| Fitness | 80—100mesh |

| Viscosity | 100 to 200000 it can be customized |